Project Overview | Technical Approach | Key Issues and Benefits | Impact and Synergies | Project Workpackages

IMC-AESOP Project Overview

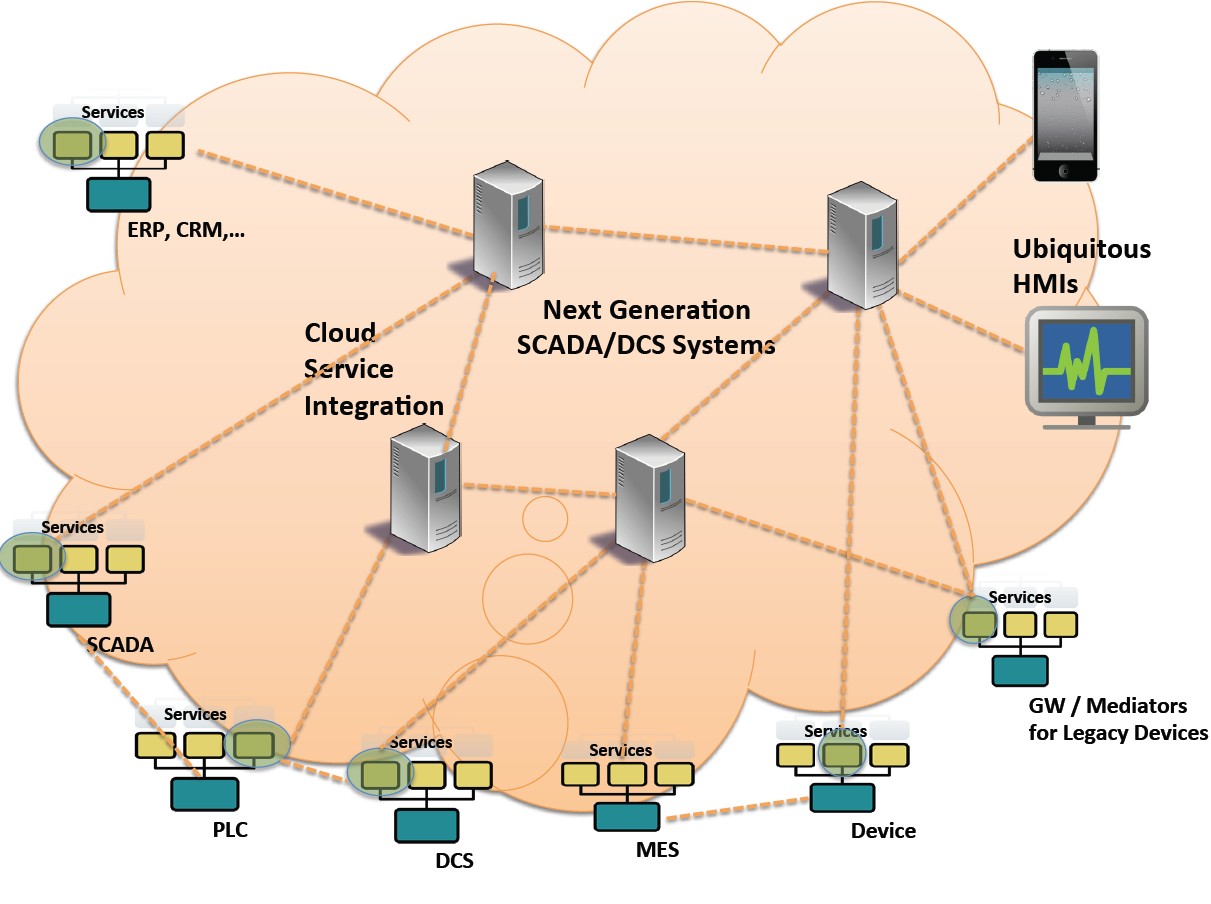

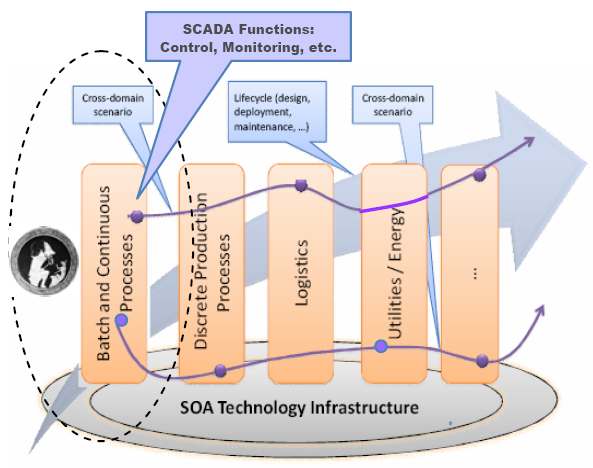

IMC-AESOP investigates a Service-oriented Architecture approach for monitoring and control of very large scale Process Control Systems (batch and continuous process applications). Large process industry systems are a complex (potentially very large) set of (frequently) multi-disciplinary, heterogeneous, networked distributed systems that function as a complex system of which the components are themselves systems, i.e. S-o-S. The future "Perfect Plant" will enable monitoring and control information flow in a cross-layer way. As such the different systems including SCADA/DCS will be part of a distributed ecosystem, where components can dynamically be discovered, added or removed, and dynamically exchange information and collaborate.

This cross-layer and cross-enterprise collaboration will be driven by business needs and enable future factories to fulfil the set of Maier's criteria. To achieve this vision, IMC-AESOP will have to deal with key challenges such as operational and managerial independence of the service-oriented constituent systems, real-time web services, interoperability, plug and play, self-adaptation, reliability, energy-awareness, high-level cross-layer integration and cooperation, event-propagation and management. The SoA-based approach proposed by IMC-AESOP can, on one hand, simplify the integration of monitoring and control systems on application layer. On the other hand, the networking technologies that are already known to control engineers could also simplify the inclusion of or migration from existing solutions and the integration of the next generation SCADA and DCS systems at network layer. Moreover, engineering methods and tools are being investigated and highlights on the domain's future will be provided by research and academic partners. IMC-AESOP will demonstrate the application feasibility in pilots, based on real-world industrial use cases provided from several end-users.

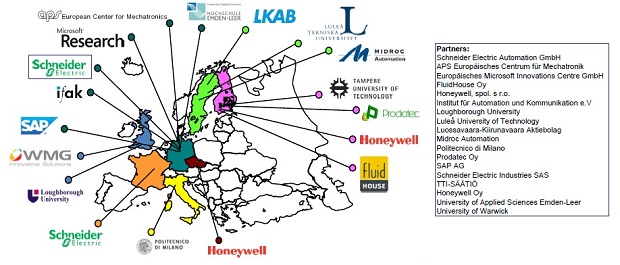

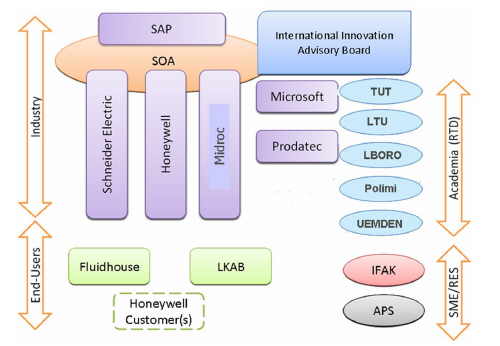

The IMC-AESOP partnership among important ICT stakeholders of the industrial value chain is a key aspect of the project that allows foreseeing important contributions to relevant standardization bodies.

IMC-AESOP Consortium

Technical Approach

IMC-AESOP envisions a SoA-based SCADA/DCS infrastructure that enables cross-layer service-oriented collaboration not only at horizontal level, e.g. among cooperating devices and systems, but also at vertical level between systems located at different levels of an enterprise architecture. The major scientific and technical objectives of the approach behind that infrastructure are:

Propose a system-of-systems approach for distributed dynamically collaborative monitoring and control based on Service-Oriented Architecture (SoA). Application for very large scale distributed systems in Process Control applications (up to tens of thousands of devices and systems exposing/consuming and processing “Services”).

Investigate how “deep in the enterprise architecture” is possible to go with SoA? Is it feasible to get SoA at the device level inside process control loops? How large is the percentage of devices that can reliably be incorporated in the SoA architecture?

Build a foundation for predictive performance of such SoA architecture based on a formal approach to event based systems.

Propose a transition path from legacy systems (e.g. a 20-year old machine) to a SoA compliant system. Propose a transition path from the new SoA-based SCADA and DCS to be an adequate legacy system in the next 20 years.

IMC-AESOP will not only design and implement this visionary infrastructure, but will also demonstrate the application feasibility in industrial pilots.

IMC-AESOP Concept: Far beyond current Process Control Systems Towards a "Distributed Dynamically Collaborative S-o-S"

Key Issues and Benefits

The application domain of process control systems composed of very large numbers of systems poses several key issues:

Distributed monitoring and control of very large scale systems (tens of thousands of interconnected devices are encountered in a single plant) enabling plant efficiency control, product quality control and production quality control.

A multitude of plant functions requesting information and functionality due to continuously changing and increasing business requirements.

Integration of existing devices which generates the data and information necessary for the multitude of plant functionalities like plant operation, maintenance, engineering, business and technology, i.e. S-o-S integration, operation and evolution.

The very large spread in device and system performance requirements regarding e.g. response time, power consumption, communication bandwidth.

Legacy compatibility (20 years old systems have to interoperate with modern systems).

When using IMC-AESOP to address those issues, the following benefits are expected:

Proactive batch and/or process automation monitoring and control systems: they are able to expose their functionalities as Services.

Open batch and/or process automation monitoring and control services that can be accessed by any other system of the enterprise architecture able to call for Services.

Proactive batch and/or process automation monitoring and control systems: they are able to compose, aggregate and/or orchestrate services exposed by themselves and from other devices in order to generate new distributed SCADA and DCS functions (also exposed as "Services").

Proactive batch and/or process automation monitoring and control systems at the shop floor, which are interoperable with SoA-based systems of the upper levels of the enterprise architecture (e.g. integrating ERP and MES with the SCADA and DCS).

Impact and Synergies

The IMC-AESOP project is looking at specification, development and prototyping distributed networked SCADA/DCS systems in automation devices and systems, by applying the SoA paradigm. As a matter of fact, Service-oriented Process Monitoring and Control as part of SCADA/DCS systems heavily depends on the integration of networked embedded systems, which is expected to grow reaching the e500 Bn in 2020. The results of IMC-AESOP will have a deep impact in that grow, expanding the potential applicability also to other domains like Energy Management, Logistics, Manufacturing, etc. Under this light the impact that IMC-AESOP would achieve might be significant and cross-domain, enabling Europe as a technology leader in Service-Oriented Process Monitoring and Control with strong synergies to the world-wide trend into System-of-Systems (S-o-S) Engineering.

IMC-AESOP Scope: Impact and Synergies

To read about the project work packages click here.